Mechanical Properties of Three Bamboo Species: Effect of External Climatic Conditions and Fungal Infestation in Laboratory Conditions

Abstract

:1. Introduction

- i.

- First, certain beetles (Hylotrupes bajulus larvae) are attracted to the starch and lay their eggs inside the culm. After that, the eggs hatch and the larvae feed along the stem and eventually through the stem walls to escape, leaving small round or oval outlet holes. The attack speed is faster on fresh green bamboo (it is more susceptible); however, even when dry, it can be attacked in warm and humid climates, where the balance moisture content of bamboo on the outside (under cover) is usually higher than that in more temperate climates [27].

- ii.

- Second, termites are little insects similar to ants that live in colonies and feed on plant material. They are also attracted to bamboo starch; however, unlike beetles, they have enzymes that allow them to break down cellulose. As they live in large colonies, they can cause short-term damage. There are two generic types of termites depending on their habitat: underground or dry wood. The former live in the ground (preferably moist), while the latter construct their nests in the wood itself or bamboo. Underground termites are translucent; thus, they build tunnels or find hidden paths to avoid sunlight [28].

- iii.

- Third, xylophagous fungi cause rot. For the fungus to thrive, the culm must be relatively wet with at least 20% moisture, which essentially means that it must be exposed to rain or soil moisture [29]. During post-harvest processing, mold and micro-fungi cause severe damage, devaluating its economic potential [8,30,31,32].

2. Materials and Methods

2.1. Materials

2.2. Methods

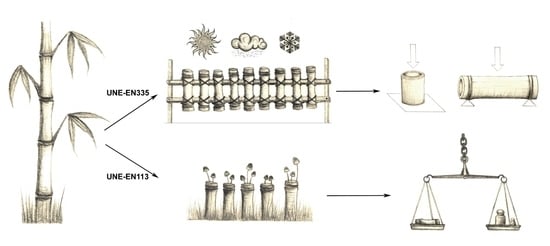

2.2.1. Durability EN 113:2021

2.2.2. Durability EN 335:2013

2.2.3. Chemical Characterization of Bamboo

2.2.4. Mechanical Tests

Bending Strength and Stiffness Parallel to the Fibers

Compression Strength and Stiffness Parallel to the Fibers

2.2.5. Density

3. Results and Discussion

3.1. Durability against Fungus Basidiomycetes

3.2. Mechanical Properties

3.2.1. Bending

3.2.2. Compression

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zou, L.; Jin, H.; Lu, W.-Y.; Li, X. Nanoscale Structural and Mechanical Characterization of the Cell Wall of Bamboo Fibers. Mater. Sci. Engingeering C 2009, 29, 1375–1379. [Google Scholar] [CrossRef]

- Li, Y.; Yin, L.; Huang, C.; Meng, Y.; Fu, F.; Wang, S.; Wu, Q. Quasi-static and dynamic nanoindentation to determine the influence of thermal treatment on the mechanical properties of bamboo cell walls. Holzforschung 2015, 69, 909–914. [Google Scholar] [CrossRef]

- Yue, J.; CaiChao, W.; Jian, L. Synthesis of carbon fiber aerogel from natural bamboo fiber and its application as a green high-efficiency and recyclable adsorbent. Mater. AMP Des. 2016, 107, 26–32. [Google Scholar]

- Lakkad, S.C.; Patel, J.M. Mechanical properties of bamboo, a natural composite. Fibre Sci. Technol. 1981, 14, 319–322. [Google Scholar] [CrossRef]

- Amada, S.; Ichikawa, Y.; Munekata, T.; Nagase, Y.; Shimizu, H. Fiber texture and mechanical graded structure of bamboo. Compos. Part B Eng. 1997, 28, 13–20. [Google Scholar] [CrossRef]

- Hsiung, W. Prospects for bamboo development in the world. Am. Bamboo Assoc. J. 1991, 8, 168–178. [Google Scholar]

- Ju, Z.; Zhan, T.; Cui, J.; Brosse, N.; Zhang, H.; Hong, L.; Lu, X. Eco-friendly method to improve the durability of different bamboo (Phyllostachys pubescens, Moso) sections by silver electrochemical treatment. Ind. Crops Prod. 2021, 172, 1–13. [Google Scholar] [CrossRef]

- Schmidt, G.; Stute, T.; Lenz, M.T.; Melcher, E.; Ressel, J.B. Fungal deterioration of a novel scrimber composite made from industrially heat treated African highland bamboo. Ind. Crops Prod. 2020, 147, 1–10. [Google Scholar] [CrossRef]

- Wei, D.; Schmidt, O.; Liese, W. Durability test of bamboo against fungi according to EN standards. Eur. J. Wood Wood Prod. 2013, 71, 551–556. [Google Scholar] [CrossRef]

- Alves, G.T.R. Aspectos da história de vida de Guadua tagoara (Nees) Kunth (Poaceae:Bambuseae) na Serra dos Órgãos, RJ. 2007; pp. 2–113. Available online: https://repositorio.ufscar.br/handle/ufscar/1998 (accessed on 14 September 2022).

- Judziewicz, E.J.; Clark, L.G.; Londoño, X.; Stern, M.J. American Bamboos; Smithsonian Books: Washington, DC, USA, 1999; pp. 1–398. Available online: https://www.cabdirect.org/cabdirect/abstract/20016783787 (accessed on 14 September 2022).

- Pereira, M.A. dos R. Projeto bambu: Introdução de espécies, manejo, caracterização e aplicações. Aleph 2012, 200, 16–210. [Google Scholar]

- Beraldo, A.; dos Pereira, M.A. Bambu de Corpo e Alma, 2nd ed.; Canal 6 Editora: São Paulo, Brazil, 2016; ISBN 9788579173936. [Google Scholar]

- Wegst, U.G.K.; Ashby, M.F. The mechanical efficiency of natural materials. Philos. Mag. 2004, 84, 2167–2186. [Google Scholar] [CrossRef]

- Deng, Q.; Li, S.; Chen, Y. Mechanical properties and failure mechanism of wood cell wall layers. Comput. Mater. Sci. 2012, 62, 221–226. [Google Scholar] [CrossRef]

- Youssefian, S.; Rahbar, N. Molecular Origin of Strength and Stiffness in Bamboo Fibrils. Sci. Rep. 2015, 5, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Murphy, R.J.; Alvin, K.L. Variation in Fibre Wall Structure in Bamboo. IAWA J. 1992, 13, 403–410. [Google Scholar] [CrossRef]

- Ray, A.K.; Das, S.K.; Mondal, S.; Ramachandrarao, P. Microstructural characterization of bamboo. J. Mater. Sci. 2004, 39, 1055–1060. [Google Scholar] [CrossRef]

- Sulaiman, O. Anatomical and physical properties of cultivated two and four year old bambusa vulgaris. 2010; pp. 571–579. Available online: https://www.academia.edu/62593008/Anatomical_and_physical_properties_of_cultivated_two_and_four_year_old_bambusa_vulgaris (accessed on 5 July 2022).

- Kaur, P.J.; Kardam, V.; Pant, K.K.; Naik, S.N.; Satya, S. Characterization of commercially important Asian bamboo species. Eur. J. Wood Wood Prod. 2015, 74, 137–139. [Google Scholar] [CrossRef]

- Elejoste, A.; Mondragon, G.; Osa, J.L.; Arevalillo, A.; Eceiza, A.; Abascal, J.M.; Butron, A.; Peña-Rodriguez, C. Banbuaren karakterizazio mekaniko eta kimikoa. EKAIA EHUko Zient. Eta Teknol. Aldizka. 2022, 1–18. [Google Scholar] [CrossRef]

- Liese, W. Anatomy and Properties of Bamboo; Institute of Wood Biology and Wood Preservation of the Federal Research Centre for Forestry and Forest Products: Hamburg, Germany, 1991; pp. 196–207. Available online: https://www.inbar.int/wp-content/uploads/2020/05/1493101748.pdf (accessed on 16 May 2022).

- Yu, H.; Jiang, Z.; Hse, C.-Y.; Shupe, T. Selected physical and mechanical properties of moso bamboo (Phyllostachys pubescens). J. Trop. For. Sci. 2008, 20, 258–263. [Google Scholar]

- Venzmer, H. Europäischer Sanierungskalender 2007: Holzschutz, Bautenschutz, Bauwerkserhaltung, Bauwerksinstandsetzung, Restaurierung und Denkmalpflege; Beuth Verlag: Berlin, Germany, 2006. [Google Scholar]

- Janssen, J.J.A. Designing and building with bamboo. Beijing Int. Netw. Bamboo Ratt. 2000, 20, 9–211. [Google Scholar]

- Shu, J.; Wang, H. Pests and Diseases of Bamboos. In Bamboos; Springer: Berlin/Heidelberg, Germany, 2015; pp. 175–192. [Google Scholar] [CrossRef]

- Liese, W.; Gutierrez, J.; Gonzalez, G. Preservation of bamboo for the construction of houses for low-income people. In Bamboo for Sustainable Development; Brill: Leiden, The Netherlands, 2002; pp. 481–494. [Google Scholar]

- Bre, B.R. Termites and UK Buildings: Biology, Detection and Diagnosis; Building Research Establishment: Watford, UK, 1999. [Google Scholar]

- Ridout, B. Timber Decay in Buildings, The Conservation Approach to Treatment. J. Preserv. Technol. 2001, 32, 58–60. [Google Scholar] [CrossRef]

- Tang, T.; Schmidt, O.; Liese, W. Environmentfriendly short-term protection of bamboo against molding. J. Timber Dev. Assoc. India 2009, 55, 8–17. [Google Scholar]

- Liese, W.; Tang, T.K.H. Preservation and Drying of Bamboo. In Bamboo: The Plant and Its Uses; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 257–297. [Google Scholar] [CrossRef]

- Schmidt, O.; Wei, D.; Bahmani, M.; Tang, H.; Liese, W. Pilzbefall und Schutz von Bambushalmen und Palmenholz—Eine Übersicht’. Z Mykol. 2015, 81, 57–80. [Google Scholar]

- Kaminski, S. Engineered bamboo houses for low-income communities in Latin America. Struct. Eng. 2013, 91, 14–23. [Google Scholar]

- Chang, W.-S.; Trujillo, D.; Ramage, M. Lightly modified bamboo for structural applications. Constr. Mater. 2013, 166, 238–247. [Google Scholar] [CrossRef]

- Rahimi, S.; Faezipour, M.; Tarmian, A. Drying of internal-check prone poplar lumber using three different conventional kiln drying schedules. J. Indian Acad. Wood Sci. 2011, 8, 6–10. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Jakovljević, S.; Lisjak, D.; Alar, Ž.; Penava, F. The influence of humidity on mechanical properties of bamboo for bicycles. Constr. Build. Mater. 2017, 150, 35–48. [Google Scholar] [CrossRef]

- Elejoste, A.; Arevalillo, A.; Gabilondo, N.; Butron, A.; Peña-Rodriguez, C. Morphological Analysis of Several Bamboo Species with Potential Structural Applications. Polymers 2021, 13, 2126. [Google Scholar] [CrossRef]

- ISO 22157:2019; Bamboo Structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/65950.html (accessed on 16 May 2022).

- UNE EN 113-2:2021; Durability of Wood and Wood-Based Products—Test Method against Wood Destroying Basidiomycetes—Part 2: Assessment of Inherent or Enhanced Durability. European Standards: Pilsen, Czech Republic, 2021. Available online: https://www.en-standard.eu/une-en-113-2-2021-durability-of-wood-and-wood-based-products-test-method-against-wood-destroying-basidiomycetes-part-2-assessment-of-inherent-or-enhanced-durability/ (accessed on 14 May 2022).

- Saha Tchinda, J.-B.; Ndikontar, M.K.; Belinga, A.D.F.; Mounguengui, S.; Njankouo, J.M.; Durmaçay, S.; Gerardin, P. Inhibition of fungi with wood extractives and natural durability of five Cameroonian wood species. Ind. Crops Prod. 2018, 123, 183–191. [Google Scholar] [CrossRef]

- Irbe, I.; Elisashvilib, V.; Asatianib, M.D.; Janbergaa, A.; Andersonea, I.; Andersonsa, B.; Biziksa, V.; Grininsa, J. Lignocellulolytic activity of Coniophora puteana and Trametes versicolor in fermentation of wheat bran and decay of hydrothermally modified hardwoods. Int. Biodeterior. Biodegrad. 2014, 86, 71–78. [Google Scholar] [CrossRef]

- Witomski, P.; Olek, W.; Bonarski, J. Changes in strength of Scots pine wood (Pinus silvestris L.) decayed by brown rot (Coniophora puteana) and white rot (Trametes versicolor). Constr. Build. Mater. 2016, 102, 162–166. [Google Scholar] [CrossRef]

- UNE EN 350:2016; Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials. European Standards: Pilsen, Czech Republic, 2016. Available online: https://www.en-standard.eu/une-en-350-2016-durability-of-wood-and-wood-based-products-testing-and-classification-of-the-durability-to-biological-agents-of-wood-and-wood-based-materials/ (accessed on 14 May 2022).

- UNE EN 335:2013; Durability of Wood and Wood-Based Products—Use Classes: Definitions, Application to Solid Wood and Wood-Based Products. European Standards: Pilsen, Czech Republic, 2013. Available online: https://www.en-standard.eu/une-en-335-2013-durability-of-wood-and-wood-based-products-use-classes-definitions-application-to-solid-wood-and-wood-based-products/ (accessed on 14 May 2022).

- De Windt, I.; Li, W.; Van den Bulcke, J.; Van Acker, J. Classification of uncoated plywood based on moisture dynamics. Constr. Build. Mater. 2018, 158, 814–822. [Google Scholar] [CrossRef]

- Floudas, D. Evolution of lignin decomposition systems in fungi. In Advances in Botanical Research; Elsevier: Amsterdam, The Netherlands, 2021; Volume 99, pp. 37–76. [Google Scholar] [CrossRef]

- Ximena Londoño, P. Distribucion, morfologia, taxonomia, anatomia, silvicultura y usos de los bambúes del nuevo mundo. In Catedra Maestria en Construcción—Modulo Guadua, Arquitectura; Universidad Nacional de Colombia: Bogotá, Colombia, 2002. [Google Scholar]

- Potenciano Marinho, N.; Nisgoski, S.; Klock, U.; Sulato de Andrade, A.; Bolzon de Muñiz, G.I. Chemical analysis of Giant Bamboo (Dendrocalamus giganteus Wall. ex Munro) at diferent ages. Ciência Florest. St. Maria 2012, 22, 417–422. [Google Scholar] [CrossRef] [Green Version]

- Fatriasari, W.; Hermiati, E. Analysis of Fiber Morphology and Physical-Chemical Properties of Six Species of Bamboo as Raw Material for Pulp and Paper. J. Ilmu Dan Teknol. Has. Hutan 2008, 1, 67–72. [Google Scholar]

- Luiz de Barros, A.; Brito, J.O.; Tomazello, M. Produção e caracterização do carvão vegetal de espécies e variedades de bambu. Inst. Pesqui. E Estud. Florestais 1987, 36, 13–17. [Google Scholar]

- Da Costa Correia, V. Produçao e Caracteriçao de Polpa Organossolve de Bambu Para Reforço de Matrizes Cimenticias; Universidade de Sao Paulo: Sao Paulo, Brazil, 2011; pp. 16–121. [Google Scholar] [CrossRef] [Green Version]

- Bhuiyan, N.H.; Selvaraj, G.; Wei, Y.; King, J. Role of lignification in plant defense. Plant Signal Behav. 2009, 4, 158–159. [Google Scholar] [CrossRef]

- Nicholson, R.L.; Hammerschmidt, R. Phenolic compounds and their role in disease resistance. Ann. Rev. Phytopath. 1992, 30, 369–389. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Zhan, H.; Ma, C.; Cai, G. Durability of Silty Soil Stabilized with Recycled Lignin for Sustainable Engineering Materials. J. Clean. Prod. 2019, 248, 119–293. [Google Scholar] [CrossRef]

- Vance, C.P.; Kirk, T.K.; Sherwood, R.T. Lignification as a mechanism of disease resistance. Ann. Rev. Phytopathol. 1980, 18, 259–288. [Google Scholar] [CrossRef]

- UNE-EN 1058:2010; Wood-based panels—Determination of Characteristic 5-Percentile Values and Characteristic Mean Values. European Standards: Pilsen, Czech Republic, 2010. Available online: https://www.en-standard.eu/une-en-1058-2010-wood-based-panels-determination-of-characteristic-5-percentile-values-and-characteristic-mean-values/ (accessed on 5 September 2022).

| Species | Origin | Altitude (m) | Precipitation (mm) | Moisture Content (%) | Zone Temperature (°C) | ||

|---|---|---|---|---|---|---|---|

| Average | Max. | Min. | |||||

| DS | Kanchanaburi (Thailand) | 400–600 | 1060 | 57–81 | 27 | 30 | 25 |

| PA | Anji County, Huzhou, Zhejiang (China) | 200–500 | 1543 | 71–80 | 18 | 28 | −3 |

| AA | 200–500 | 1543 | 71–80 | 18 | 28 | −3 | |

| Species | Description | Moisture Content (%) | Density (kg/m3) | Height (m) | Diameter (mm) | Age (Years) | |

|---|---|---|---|---|---|---|---|

| ρ (Culm Wall) | ρ′ (Total) | ||||||

| DS | Cylindrical and solid form | 6.60 ± 0.70 | 624 | 624 | 5–15 | 30–50 | 3–4 |

| PA | Cylindrical and hollow form | 5.47 ± 0.61 | 863 | 362 | 6–9 | 30–50 | 3–4 |

| AA | Cylindrical and hollow form | 5.72 ± 0.15 | 940 | 497 | 6–13 | 20–60 | 3–4 |

| Dimension (mm) | Bending | Compression | ||||

|---|---|---|---|---|---|---|

| DS | PA | AA | DS | PA | AA | |

| Lb, Lc | 180–360 | 130–350 | 170–420 | 180 | 150 | 180 |

| D | 27–41 | 27–33 | 31–38 | 28–39 | 27–33 | 28–38 |

| d | 0 | 17–31 | 21–29 | 0 | 20–26 | 21–28 |

| EN 350:2016 | EN335 CU3.1 | |||

|---|---|---|---|---|

| Species | ML1 (%) | Durability Class | Description | ML2 (%) |

| DS | 3.95 | DC1 | Very durable (ML ≤ 5) | 15.28 |

| PA | 5.65 | DC2 | Durable (5 < ML ≤ 10) | 10.15 |

| AA | 3.02 | DC1 | Very durable (ML ≤ 5) | 7.85 |

| PS | 56.71 | DC5 | No durable (30 < ML) | ------- |

| Species | Composition | |

|---|---|---|

| Extractives (%) | Lignin (%) | |

| DS | 12.12 ± 0.05 | 23.80 ± 5.50 |

| PA | 14.71 ± 1.46 | 18.37 ± 1.55 |

| AA | 9.70 ± 1.34 | 28.85 ± 3.62 |

| PS [48] | 0.90 | 25.4 ± 8 |

| Bibliography [22,49,50,51,52] | 0.91–10.91 | 22.66–24.11 |

| DS | PA | AA | ||||||

|---|---|---|---|---|---|---|---|---|

| Time (Months) | 0 | 6 | 0 | 6 | 0 | 6 | ||

| Bending | Average | σbf (MPa) | 90.3 ± 27.2 | 77.5 ± 16.6 | 40.5 ± 7.0 | 50.6 ± 25 | 55.3 ± 7.7 | 52.7 ± 11.5 |

| Eb (MPa) | 3234 ± 2181 | 3932 ± 2010 | 4091 ± 1898 | 2960 ± 2427 | 6689.5 ± 2454.7 | 4846 ± 2116 | ||

| 5th percentile | σbf (MPa) | 58.5 | 52.2 | 31.6 | 30.1 | 45.1 | 36.3 | |

| Eb (MPa) | 921 | 1192 | 2042 | 1185 | 3039 | 1894 | ||

| Compression | Average | σcf (MPa) | 50.4 ± 10.5 | 29.5 ± 7.7 | 71.4 ± 11.5 | 66.7 ± 8.7 | 78.2 ± 10.8 | 71 ± 13.2 |

| Ec (MPa) | 4249 ± 1180 | 2674 ± 822 | 6555 ± 1605 | 5895 ± 1674 | 6645 ± 1921 | 6577 ± 1713 | ||

| 5th percentile | σcf (MPa) | 36.6 | 20 | 50.0 | 54.9 | 61.1 | 46.7 | |

| Ec (MPa) | 2454 | 1604 | 3818 | 4105 | 4513 | 3943 | ||

| Densities | ρ (kg/m3) | 624.45 | 529 | 862.55 | 775 | 939.85 | 866 | |

| ρ′ (kg/m3) | 624.45 | 529 | 362.00 | 302 | 497.00 | 387 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elejoste, A.; Osa, J.L.; Arevalillo-Roman, A.; Eceiza, A.; Abascal, J.M.; Rico-Martinez, J.M.; Butron, A.; Peña-Rodriguez, C. Mechanical Properties of Three Bamboo Species: Effect of External Climatic Conditions and Fungal Infestation in Laboratory Conditions. Forests 2022, 13, 2084. https://doi.org/10.3390/f13122084

Elejoste A, Osa JL, Arevalillo-Roman A, Eceiza A, Abascal JM, Rico-Martinez JM, Butron A, Peña-Rodriguez C. Mechanical Properties of Three Bamboo Species: Effect of External Climatic Conditions and Fungal Infestation in Laboratory Conditions. Forests. 2022; 13(12):2084. https://doi.org/10.3390/f13122084

Chicago/Turabian StyleElejoste, Asier, Juan Luis Osa, Alfonso Arevalillo-Roman, Arantxa Eceiza, Jose Miguel Abascal, Jose Miguel Rico-Martinez, Amaia Butron, and Cristina Peña-Rodriguez. 2022. "Mechanical Properties of Three Bamboo Species: Effect of External Climatic Conditions and Fungal Infestation in Laboratory Conditions" Forests 13, no. 12: 2084. https://doi.org/10.3390/f13122084