1. Introduction

Fruits and vegetables are vital parts of a nutritious diet. They contain essential minerals, vitamins, and fibre to promote overall wellness and good health. Consuming a variety of fruits and vegetables has been linked to a lower risk of chronic diseases such as stroke, heart disease, and certain cancers [

1]. Additionally, the regular consumption of fruits and vegetables could help manage weight, improve digestion, and boost immunity. Northeast India is a treasure trove of underutilised fruits that are not only delicious but also packed with nutrients and health benefits. These fruits are unique to the region and have been traditionally used by the local communities for centuries but remain largely unknown to the outside world [

2].

Lapsi (

Choerospondias axillaris) is a lesser-known fruit native to Bhutan, Nepal, and parts of Northeast India (Sikkim, Arunachal Pradesh, and Assam) [

3]. At the beginning of spring, the lapsi tree produces tiny, light-greenish blossoms that are accompanied by tiny, oval fruits around 2–3 centimetres in diameter. When fully ripe, the fruit turns yellow or red and possesses a sour, tart flavour. It has various nutrients (vitamin C, vitamin A, and dietary fibre), possesses numerous health benefits, and is known for its antioxidant, antimicrobial, and anti-inflammatory properties [

4]. The fruit has been traditionally used in one of the world’s oldest medical systems, Ayurvedic medicine, India’s traditional health system. The fruit has a unique sour and sweet taste and is used in various culinary preparations, such as pickles, jams, and chutneys.

As lapsi fruits are perishable in nature, it is essential to prevent their loss and promote their use by processing them into value-added products such as fruit juices [

5]. The processing of fruits into juices may help to maintain the freshness and long-term viability of the fruits, as well as increase their monetary and nutritional value. It is essential to explore various processing methods and techniques to ensure that the fruits are processed in a safe and sustainable manner while retaining their essential nutrients and sensory properties.

Thermal treatment, such as pasteurisation (PS), is required to ensure the safety and quality of fruit juices [

6]. Pasteurisation is a heat-treatment technique that eliminates potentially harmful microorganisms from fruit juices. In addition, by preventing microbial deterioration, it can aid in extending the shelf life of juices [

7]. Heat-sensitive micro-nutrients (vitamins) in fruit juices may break down due to the high temperatures used during PS, lowering their nutritional value [

8]. Furthermore, the heat may alter the juice’s flavour, aroma, and colour, which may impact its sensory qualities. Alternatives to thermal processing in the manufacturing of fruit juices include non-thermal methods like ultrasonication, cold plasma, irradiation, membrane filtration, ozone treatment, and high-pressure processing (HPP) [

9]. While ensuring its safety and extending its shelf life, these methods can aid in maintaining the juice’s nutritional and sensory qualities.

A promising non-thermal technology known as ultrasound (US) treatment can successfully remove microorganisms from fruit juices with little to no effect on nutritional and sensory qualities. Due to its various benefits over conventional thermal processing techniques, this novel method can greatly benefit the fruit juice industry. Thermosonication (TS), a type of ultrasonication method, uses heat and high-frequency sound waves (ultrasound) for food preservation. It involves heating food to a specific temperature (typically between 50 °C and 80 °C) and then exposing it to high-frequency sound waves (typically between 20 kHz and 100 kHz) [

10]. The emergence and ensuing disintegration of tiny air bubbles in a liquid is known as cavitation, and it is the main physical mechanism that occurs in thermosonication. These air bubbles form as a result of the passage of ultrasound waves through the liquid. When the air bubbles implode, they raise the surrounding temperature and pressure. This causes localised turbulent flows and vibrations that aid in rupturing the cell walls and releasing the desired compounds [

5].

Several researchers have shown the preservative effect of ultrasound on fruit juices, including [

11] pomelo juice and [

12] kutkura juice. According to Boghossian et al. [

13], ultrasound is a well-known method for producing fruit juices of superior quality because it retains more bioactive compounds than thermal methods alone.

An artificial neural network (ANN) is a machine-learning algorithm that draws inspiration from the structure and operations of the human cerebral cortex. ANNs consist of interconnected nodes, often referred to as “neurons,” which play the crucial roles of processing and transmitting data [

14]. The steps involved in creating an ANN consist of collecting the data, organising it, training the ANN, testing it in order, analysing its performance, and using it to predict outcomes from new input data. ANNs can be used to create predictive models for complex systems in the context of modelling and optimisation, where conventional mathematical models might not be practical [

14]. Based on different processing parameters, they can be used to simulate food processing operations and forecast significant quality attributes. By doing so, the processing conditions can be improved to produce the desired quality attributes while lowering costs and generating less waste. In a variety of industries, including food processing, ANNs provide a versatile and potent tool for modelling and optimisation. They have been used by several researchers to model and optimise process variables for various fruit juices, including cashew apple juice [

15], bael fruit juice [

16], and red plum juice [

17]. It is clear that ANNs offer multiple advantages over other popular optimisation tools, including response surface methodology such as flexibility, non-linearity, robustness, parallel processing, learning and adaptation, lack of prior knowledge requirements, and generalisation.

To date, there have been no reports on the use of thermosonication for the processing lapsi fruit juice. Thus, the objective of this study was to utilise both thermosonication and thermal pasteurisation to process lapsi fruit juice and to assess the resulting influence on the physicochemical, nutritional, and microbiological properties of the juice. Additionally, an ANN model was created to forecast the optimisation of process parameters for the quality of lapsi fruit juice for maximum retention of nutritional properties, improvement of juice quality, and increased efficiency.

2. Materials and Methods

2.1. Lapsi (Choerospondias axillaris) Fruit Sample

Mature and flawless lapsi fruits, freshly harvested from a garden in the vicinity of Ranipool, Sikkim, were carefully collected and transferred using an insulated container (sterile ice box maintaining 4 °C) to the laboratory of the Department of Food Engineering and Technology, CITK, Kokrajhar. The fruits were removed from their stalks, washed in water, allowed to air dry, and sliced into small pieces before the juice was extracted.

2.2. Chemicals

The chemicals utilised in this study were obtained from two different sources, namely Bengaluru-based Sigma Aldrich and Mumbai-based HiMedia Chemicals, nestled in India. Additionally, the chemicals utilised to determine microbiological properties, including potato dextrose agar, total plate count agar, and peptone water, were acquired from MERCK Group.

2.3. Juice Preparation

Slices of lapsi fruit (approximately 2–3 cm in size) were crushed using a domestic grinding device (mixer). After that, Whatman number one filter paper was used to eliminate any remaining impurities and clarify the juice. Three separate treatment groups of the juice were established as follows: the raw juice (control), the pasteurised lapsi juice (PSLJ), and the thermosonicated lapsi juice (TSLJ). All juice samples were processed immediately after their separation on the same day.

2.4. Pasteurisation of the Juices

Lapsi fruit juices were thermally treated in an experimental establishment employing a vertical pasteuriser at a temperature of 90 °C for a duration of 60 s [

12]. After pasteurisation, the samples were cooled in an ice bath. The chosen pasteurisation conditions were aimed to mimic the industrial processing of juices, which typically involves using temperatures ranging from 90 to 95 °C for about 15 to 60 s to reduce the number of microorganisms up to 5 logs. SJ was treated at 90 °C for 60 s with PS.

2.5. Thermosonication of the Juices

Thermosonication treatments on juice samples were conducted using an ultrasonicator probe (Sonics and Materials, Inc., Newton, CT, USA) at various temperatures (30, 40, and 50 °C) with 750 W full power [

18]. Juice samples (100 mL) were treated at intervals of 15, 30, 45, and 60 min at three different amplitudes (50%, 75%, and 100%) [

19,

20]. The sonication was conducted under dark conditions to avoid any interaction with light. After sonication, the juice samples were transferred to sterilised containers and stored at 4 °C until further analysis. The processing of lapsi fruit juice is represented in

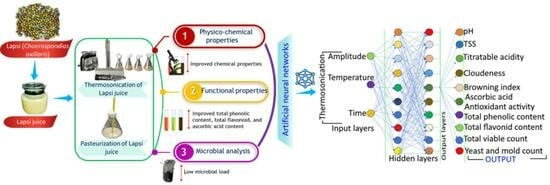

Figure 1.

2.6. Determination of Physicochemical Properties

2.6.1. pH, Total Soluble Solids, and Titratable Acidity

The pH levels of both control and treated lapsi juice samples were measured at 25 ± 1 °C applying a digital pH meter [

21]. The concentration of total soluble solids (TSSs) of lapsi juice was analysed by employing a refractometer, and the results were reported in the form of Brix degrees (°Brix) [

22]. The titratable acid concentration (TA) of both control and treated lapsi juice samples was assessed using the AOAC [

21] method. The results were expressed as a citric acid percentage [

12]. The results for each sample were taken in triplicate and an average was taken for every analysis.

2.6.2. Cloudiness and Browning Index

Centrifugation was carried out using 5 mL samples of both treated and untreated LJ at room temperature for estimating the cloudiness (CI) and browning index (BI). The centrifugation was performed using a centrifuge (Remi C-24BL, Remi Elektrotechnik Ltd., Mumbai, India) spinning at 6000 rpm for a duration of 10 min. After the centrifugation process, the supernatant was utilised to determine CI and BI. To assess the degree of cloudiness, the absorbance was measured at 660 nm using a UV-Vis spectrophotometer (PerkinElmer Lambda 35 UV/VIS, PerkinElmer, Inc., Waltham, MA, USA) [

23]. In order to determine the browning index of both treated and untreated LJ, 5 mL of supernatant was mixed with 5 mL of ethanol. The mixture was thoroughly combined, and its absorbance at a wavelength of 420 nm was subsequently measured using a UV-Vis spectrophotometer [

23].

2.7. Determination of Functional Properties

2.7.1. Ascorbic Acid Content

The level of ascorbic acid content (AA) in LJ samples was measured by employing the iodine titration method [

24]. Soluble starch (0.25 g) was dissolved in a 100 mL conical flask with 50 mL of near-boiling water. After cooling, a separate mixture of potassium iodide (2 g) and iodine (1.3 g) was dissolved in distilled water and transferred to a 1 L volumetric flask. Samples (raw, PSLJ, and TSLJ) were diluted with distilled water (20 mL) and starch indicator (1 mL) in 250 mL conical flasks. Titration with a 0.005 mol/L iodine solution revealed the first permanent trace of a dark blue-black colour, indicating the starch-iodine complex formation. The amount of ascorbic acid present in the juices was indicated by stating the quantity as milligrams of ascorbic acid per 100 mL of the sample.

2.7.2. Antioxidant Activity

The antioxidant activity (AOA) of samples (lapsi juice) was evaluated using the DPPH (2,2-diphenyl-1-picrylhydrazyl) scavenging method [

25]. A measured volume of the juice sample (2 mL) was combined with 2 mL of a DPPH solution (0.2 mM in ethanol), and this resulting mixture was placed in a dark environment at room temperature (25 ± 1 °C) for 30 min. A similar procedure was employed for the blank, but instead of the sample, ethanol was used. Subsequently, the absorbance values of the samples were determined at 517 nm using a UV spectrophotometer. The DPPH radical scavenging activity was calculated as a percentage (%) using the following Formula (1):

where A

o = absorbance of the control, and A

1 = absorbance of the juice.

2.7.3. Total Phenolic Content

The determination of the total phenolic compounds present in both treated and untreated fruit juices was conducted using the method suggested by Nayak et al. [

26]. LJ was mixed with 0.1 mL of diluted Folin–Ciocalteu reagent, followed by a 3 min incubation. Then, 0.3 mL of 20 g/L sodium carbonate solution was added. After 2 h, absorbance was measured at 760 nm using a spectrophotometer. The findings of the trials were presented as milligrams of gallic acid equivalent (GAE) per mL of juice.

2.7.4. Total Flavonoid Content

The total flavonoid content (TFC) of lapsi juice samples was determined using the approach laid out by Nayak et al. [

22]. A 6 mL LJ sample was mixed with 0.2 mL of a 10%

w/

v aluminium chloride and 5% sodium potassium tartrate solution. After adding 5.6 mL of distilled water, the solution was incubated in the dark for 30 min. Absorbance at 415 nm was measured using a spectrophotometer, and a calibration curve was generated using catechin as the standard. The concentration of flavonoids in the lapsi juices was denoted as milligrams of catechin equivalent (CE) per mL of juice.

2.8. Determination of Microbial Attributes

Microbiological determination was performed to determine the total plate counts as well as total yeast and mould counts (YMC) of lapsi juices by the method followed in the work of Tomadoni et al. [

27]. For total plate count, juice samples were spread on plate-count agar and incubated at 37 ± 1 °C for 48 h. Similarly, YMC was determined by spread-plating samples on potato dextrose agar and incubating at 37 ± 1 °C for 72 h. Colonies were counted after the completion of incubation periods and the results were expressed as log cfu/mL.

2.9. Experimental Design for Optimisation

Artificial Neural Network Modelling

Using MATLAB R2020a software, artificial neural networks were created to generate predictive analytics for examining the physicochemical, functional, and microbial characteristics of LJ samples that underwent thermosonication. Preliminary studies were used to designate the input parameters and their ranges. The independent variables included thermosonication amplitude X1 (50%, 75%, and 100%), thermosonication temperature X2 (30, 40, and 50 °C), and treatment time X3 (15, 30, 45, and 60 min). The output parameters considered in this study were pH, TSS, TA, cloudiness, browning index, ascorbic acid, antioxidant activity, TPC, TFC, and YMC. The 36 experimental data points were randomly divided into three sets for training (75% of the data), validation (15% of the data), and testing (15% of the data) purposes. The structure of the well-trained ANN model with the optimal topology was (3:10:10), where the weights of connections between neurons in different layers and the bias or threshold values of hidden- and output-layer neurons were organised in matrix form with a network-type feed-forward backprop along with a training function (TRAINLM). Specifically, the matrix size of the weights of synaptic connections between input- and hidden-layer neurons was 10 × 3, and the matrix size of the weights of connections between hidden- and output-layer neurons was 10 × 10. Finally, the matrix size of the bias or threshold values of hidden- and output-layer neurons was 10 × 1 and 10 × 1, respectively. The adaption function was set at LEARNGDM with transfer function PURELIN. Preliminary experiments were conducted with treatment temperatures ranging from 30 °C to 50 °C, which were determined by referring to previous studies that reported the extraction of different fruit juices using ultrasonication [

28,

29]. The fitness of ANN models was evaluated using coefficient of determination (R

2), mean absolute error (MAE), and mean square error (MSE) values, which were determined using Equations (1)–(3) [

29].

The variables used in this context are for experimental data, for predicted values, x representing the mean value of experimental data, y representing the mean value of predicted data, and n representing the total number of observations.

R-squared (R2) is a statistical measure that represents the proportion of the variance in the dependent variable (the variables to predict) that is explained by the independent variables (the inputs to model). In the context of evaluating ANN models, R2 is often used to assess how well the model captures the variation in the target variable. It ranges from 0 to 1, with higher values indicating a better fit. An R2 value of 1 means the model perfectly predicts the target variable, while an R2 of 0 means the model provides no improvement over a simple mean prediction. MAE is a common metric used to measure the average absolute difference between the actual values and the predicted values. It quantifies the average magnitude of errors in the predictions made by the model. Smaller MAE values indicate better accuracy, as they imply that the model’s predictions are closer to the actual values on average. MSE is another common metric used to measure the average squared difference between the actual values and the predicted values. It squares the errors, giving more weight to larger errors. Like MAE, a lower MSE indicates better accuracy, with values closer to zero implying better model performance.

2.10. Statistical Analysis

All experimental analyses were conducted in triplicate, and the results were presented as mean ± standard deviation. To assess the statistical significance, the data were subjected to analysis of variance (ANOVA) using SPSS version 16.0, with a predetermined significance level of p < 0.05.

4. Conclusions

The current investigation used a multi-layer ANN to model and optimise the ultrasound-assisted extraction of lapsi juice. The influence of thermosonication at various levels of amplitude, temperature, and time on various responses such as physicochemical (pH, TSS, TA, CI, and BI), nutritional (AA, AOA, TPC, and TFC), and microbiological (total plate count and YMC) properties was also ascertained. The maximum levels of AA (71.80 ± 0.05 mg/100 mL), AOA (74.60 ± 0.28%), TPC (187.33 ± 0.03 mg GAE/mL), and TFC (127.27 ± 0.05 mg QE/mL) were obtained. The microbial populations in TS samples were recorded as lower than those in fresh samples and were attained by total plate count (not detected) and YMC (2.02 ± 0.02 log cfu/mL) in TSLJ under optimal TS conditions. For AA and TFC, the optimal conditions were 100% amplitude, 40 °C, and 45 min. For AOA and TPC, the optimal conditions were 100% amplitude, 40 °C, and 60 min, and for YMC, the optimal conditions were 100% amplitude, 50 °C, and 60 min. The high R values indicated a high degree of concurrence among the actual and predicted values. The optimal extraction variables have been identified using an established ANN as follows: The ideal conditions for processing lapsi juice with thermosonication have been identified through ANN and are listed following 20 iterations. The actual responses at the optimised process parameters closely matched the predicted values acquired from the established ANN model. In accordance with the outcomes, thermosonication might serve as an intriguing alternative to thermal pasteurisation for preserving lapsi juice while minimising or avoiding quality deterioration and augmenting functional attributes.

Industrial Relevance

Ultrasound-assisted extraction (UAE) is an innovative method that is gaining popularity in a variety of industries, including the food and beverage industry. When it comes to the extraction of lapsi fruit juice, UAE provides several benefits and has significant industrial significance. UAE not only improves extraction efficiency and speed, but it also improves the quality of lapsi fruit juice. The moderate and non-thermal nature of ultrasonic waves reduces the breakdown of heat-sensitive components found in fruit, such as vitamins, enzymes, and antioxidants. As a result, the extracted juice maintains its nutritious value, brilliant colour, and flavour profile. This element of UAE quality preservation is very important for the food and beverage industry, as customers are increasingly looking for natural and less processed products. It is the best option for the food and beverage industry because of its adaptability in terms of process parameters and its ability to improve extraction efficiency, speed, and quality. UAE represents a viable technique for industrial-scale lapsi fruit juice extraction, providing firms with a competitive edge in the market with the added advantages of sustainability and environmental concern.